Canadian Safety Datasheet

Stainless Steel Glue

Product # HR19133100000

Structural Bonding

This glue has the strength of an epoxy and the speed of an instant adhesive.

It cures in minutes, making it ideal for applications requiring quick bonding.

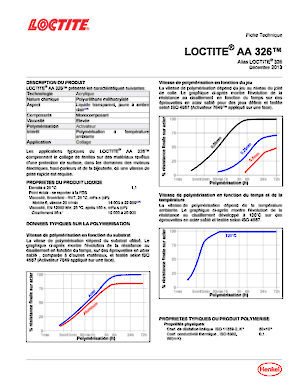

Description of the product - volume: 50 ml; color: amber; gap fill: 0.02; tensile strength: 2,700 psi; viscosity: 18,000 cP; temperature range: from -54°C (-65°F) (min.) to 107°C (225°F) (max.); setting time: 1 min to 25°C (77°F); full curing time: 24 h at 25°C (77°F).

It cures in minutes, making it ideal for applications requiring quick bonding.

Description of the product - volume: 50 ml; color: amber; gap fill: 0.02; tensile strength: 2,700 psi; viscosity: 18,000 cP; temperature range: from -54°C (-65°F) (min.) to 107°C (225°F) (max.); setting time: 1 min to 25°C (77°F); full curing time: 24 h at 25°C (77°F).

ADVANTAGES AND BENEFITS

Drying time can be reduced with the use of an activator

Product for bonding magnets

Medium viscosity (thixotropic)

Good adhesion on different types of ferrite

Product for bonding magnets

Medium viscosity (thixotropic)

Good adhesion on different types of ferrite

REQUIRED PRODUCTS

Requires the following products

TECHNICAL SPECIFICATIONS

Product #

HR19133100000

Volume

50 ml

Weight

1.1 oz

Finish/Color

Yellow

Viscosity

18 000 cps

Brand

Loctite®

Recommended Use

Durable Assembly Adhesive

APPLICATION

Recommended for most metals and glass.

Resistant to the weather and solvents.

Tips for application

1. For best results, clean surfaces of dirt and grease

2. To ensure quick and reliable curing, apply the 7649TM activator on one side and the glue on the other. Assemble the parts within 15 minutes.

3. The recommended clearance is 0.1 mm. For larger clearances (up to 0.5 mm) or for quicker setting, apply the 7649TM activator on both sides. Assemble parts immediately (within one minute).

4. Remove excess glue with a paper soaked in organic solvent.

5. Maintain light pressure on the parts until the glue sets.

6. Wait until the product has acquired all its qualities before using it (generally between 24 and 72 hours after assembly, depending on the clearance, the materials and the ambient conditions).

Resistant to the weather and solvents.

Tips for application

1. For best results, clean surfaces of dirt and grease

2. To ensure quick and reliable curing, apply the 7649TM activator on one side and the glue on the other. Assemble the parts within 15 minutes.

3. The recommended clearance is 0.1 mm. For larger clearances (up to 0.5 mm) or for quicker setting, apply the 7649TM activator on both sides. Assemble parts immediately (within one minute).

4. Remove excess glue with a paper soaked in organic solvent.

5. Maintain light pressure on the parts until the glue sets.

6. Wait until the product has acquired all its qualities before using it (generally between 24 and 72 hours after assembly, depending on the clearance, the materials and the ambient conditions).

IMPORTANT INFORMATION

Setting time: 3 min

Maximum admissible temperature: up to 120 °C (248 °F)

This product is not recommended in facilities where pure oxygen or mixtures rich in oxygen circulate. It should not be used as a watertight product coming into contact with chlorine or other highly oxidizing bodies. For information on the risks associated with using this product, consult the related safety data sheet (SDS).

Maximum admissible temperature: up to 120 °C (248 °F)

This product is not recommended in facilities where pure oxygen or mixtures rich in oxygen circulate. It should not be used as a watertight product coming into contact with chlorine or other highly oxidizing bodies. For information on the risks associated with using this product, consult the related safety data sheet (SDS).